To Retrofit Or Not To Retrofit, That Is The Question! - Tim Terry (PRO-DAIRY)

To Retrofit Or Not To Retrofit, That Is The Question!

July 2022, by Tim Terry (PRO-DAIRY)

Dairy farming is a constantly changing business. Farming for the long-term will require a facility that can change, as well. Expansion, new technology, and new enterprises may all be in every sustainable farm's future. Planning for a new, or remodeling and retrofitting an existing facility, is best done carefully and thoughtfully. We have all seen farms laid out in a chaotic array of buildings, and driveways that are inefficient now and make future improvements difficult or even impossible.

Why retrofit?

The short answer to this question is often, "Efficiency."

Figure 1 - Robotic milking units retrofitted into an existing holding area.

For the sake of production efficiency, the farm is trying to incorporate a new technology, for the sake of investment efficiency they are trying to do so in an existing structure. Most of the time this a sound business strategy, unfortunately, if all aspects are not carefully and dispassionately considered, this could lead to a false economy.

Regarding new versus retrofitting an existing facility consider first the condition of the facility. If it is not meeting expected standards in terms of animal comfort and ventilation or lacking in any manner of internal environment then that's a deal breaker. The only job of many of these new technologies (robotic milkers, calf feeders) is to perform rote tasks and collect data. So, then the question becomes: Do we remodel / renovate or build new?

A helpful guideline is: If the retrofit/remodel is 50% or more of a new facility, go for the new facility. The 50% is not a hard line and there can be a certain amount of discretion included in that, however, there are three reasons that support this:

1. We tend to overestimate the value of the existing structure. There is almost always the sentimentality factor, and it can be very hard to walk away from, let alone raze, the building Great Grandpa constructed with his own two hands from the raw materials he found on site. However, we need to see this as sunk capital. Just as if it were sitting on the bottom of the ocean, it is gone, the investment is unrecoverable, and throwing more good money after it is not a wise use of resources.

2. We tend to underestimate the cost of remodeling and/or upgrading the facility to accept the new technology. Quite often we can't appreciate the full scope of the project until we start peeling back the layers and exposing the hidden structure. We may not even be able to install the new system without compromising the structural integrity of the facility. Many may feel they can reduce expenditures by doing it themselves but fail to consider the disparity in skill levels between themselves and the professionals, the amount of tinkering required to retrofit 21st century technology into a 19th century building, the availability of the necessary tools and materials, and lastly, how they're going to fit it in with daily chores, planting, harvesting, etc.

3. We fail to properly value the cost of long-term inefficiencies that remain with the old facility. Even if it takes only five minutes per day that's over a half hour per week and 30 hours per year. However, it's rarely just five minutes or only one person. Add to this the potential reduction in animal performance.

Other Considerations

Space - Is there enough available space to install the new technology, allow it to work effectively, and be able to maintain it efficiently? Will there be room for upgrades and/or expansion? It is very short-sighted to shoehorn a system into an old facility with no room for future improvements. Moreover, local codes may specify space requirements and/or minimum separation distances.

Layout and number of units - Can we install the correct number of units required to service the current number of animals? Will the layout be logical and efficient? Many systems will use a common controller for multiple units, but they must be within a certain distance. For robotic milking systems will the units be in reasonable proximity to the collection point (milkhouse)? Will the units be able to clean and sanitize the system to meet health code regulations?

Ingress and egress - Livestock, especially large livestock, require certain minimum dimensions for passageways, turning radius, and head-to-head intersections. They also don't like apparent dead ends, mazes, dark areas, or shadows on the floor. Travel lanes should never require an animal to step up or down and change direction all in the same movement (i.e. - entering/existing a foot bath). Whenever possible, entry and exit should be straightforward. It should also allow for them to fully pass through a one-way gate before changing direction.

Ventilation - Whether the facility is naturally or mechanically ventilated, you will most likely have to provide some supplemental ventilation in and around the particular units. Circulation fans can boost air flow over a control room in tunnel and cross vented barns. Having a dedicated fan over a milking or feeding stall will keep fresh air moving in the confined space as well as deterring biting flies in the summer.

Ancillary Items

Footbaths - Footbaths should be placed where they are easy to access and easy to exclude. They also need to be narrow (24"- 32") and 10' to 12' long. This will keep animals moving while also forcing multiple submersions of all feet. At least one side should be able to open out should an animal go down and not be able to get back on their feet. Emptying, cleaning, and recharging must be easy to complete, or it may not be done in a timely manner.

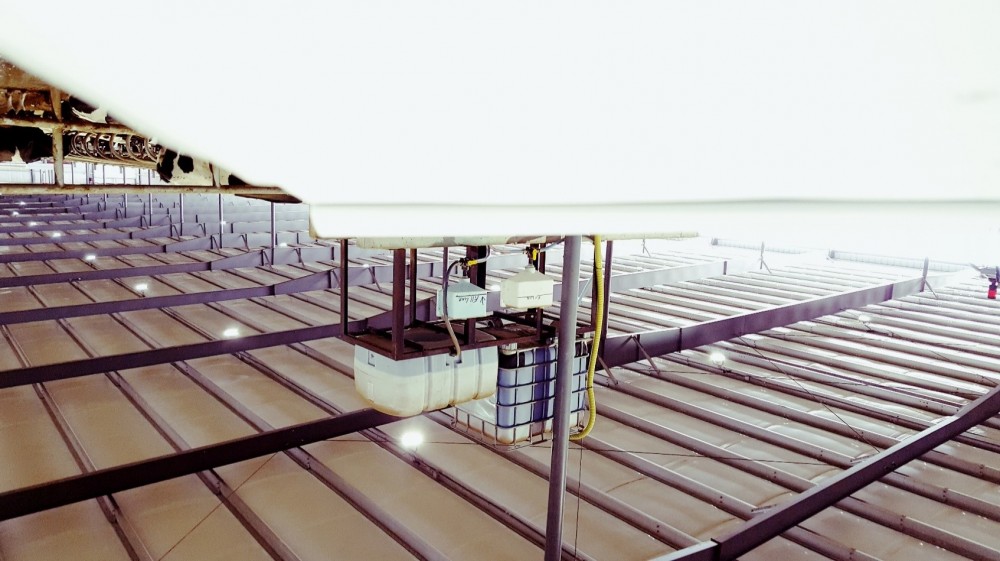

Figure 2 - Elevated totes of premixed footbath solution.

Drain plugs and frostless hydrants need to be included in the design. Some farms elevate a tote of premixed solution over the footbath so that it may be quickly refilled.

Segregation pens - Many may see this as wasted space since it is so infrequently occupied. However, when coupled with a robotic milking system (RMS) it allows for full use of the herdsman abilities of the RMS. Any cow requiring special attention can be redirected to this pen following milking. Then the herdsman, vet, breeder, etc. can find the animal without having to search the entire group pen. In the meantime, the animal still has access to feed, water, a stall in which to rest, with full access to the robot.

Treatment Stall - Even in the healthiest of herds, at some point all animals will need to be vaccinated, hoof trimmed, dry treated, etc. These activities cannot and should not be completed in the milking stall. The treatment stall is usually located in or near the segregation pen for easy access. Gating should be set up such that one person can move an animal quickly, quietly, and safely with little effort. Ideally, there should be a minimum of 6' of open space around the perimeter of the stall. This provides ease of access to the animal as well as an escape zone should an animal become unruly

Authors

Timothy X. Terry

Email: txt2@cornell.edu

Factsheet - PDF (pdf; 334KB)

Upcoming Events

WEBINAR - Automated Milking Systems Efficiency: Balancing Focus on Individual Cows and System Optimization

May 8, 2024

Please join Cornell the SWNY team and MSU Extension for our talk with Dr. Pablo Silva Boloña on improving efficiency of Automated milking systems by focusing on milking settings for individual and group success.

Broiler Field Day at Sunny Cove Farm

June 6, 2024

Alfred Station, NY

Join us for a field day to explore broiler production, processing, and finances. Meghan Snyder of Sunny Cove Farm will be our host. She raises small batches of organic broilers, processing them on-farm under the 1,000 bird exemption.

Cornell Seed Growers Field Day

July 2, 2024

Ithaca, NY

Please Save the Date for the Cornell Seed Growers Field Day to be held the morning of July 2nd. The event will be held at the NYSIP Foundation Seed Barn, 791 Dryden Rd., Rt. 366, Ithaca, NY.

Announcements

No announcements at this time.